Producing quality

hose assemblies

Producing quality

hose assemblies

with UNIFLEX machines

All over the world, UNIFLEX’S highly effective machines are being used to produce quality hose assemblies. Recognized as the leading supplier, UNIFLEX makes machines that can efficiently and precisely manufacture hose assemblies that meet the most exacting standards.

Using the latest technology in the design and construction of the machines and in close collaboration with the hose and coupling manufacturers, UNIFLEX provides companies with the tools to succeed.

Safe products that are made using machines that are safe to use… that is a winning combination.

Clean and correctly

cut hose

Exact skived hose

– internal and external

Safety crimped fitting

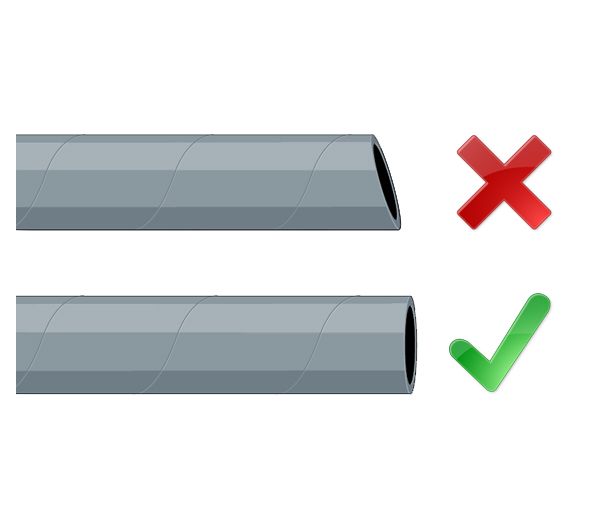

The key to achieving consistent hose lengths and good quality hose assemblies is dependent on achieving a straight and clean cut. The selection of machine and the type of cutting blade depends to the types of hose and the nominal diameters (DN).

Impurities in the hose, highlighted by residual particles and cutting residues, may damage hydraulic systems which can reduce performance or lead to a catastrophic and costly failure!

Sources of errors in the cutting

- Improper cutting machine

- Blades not sharply ground

- Hose not prebent

- Oblique cut, rough hose end

Potential risk by incorrect cutting

- Contamination of the hydraulic system

- Leakage in the hose connection

- Premature tearing of the hose fitting

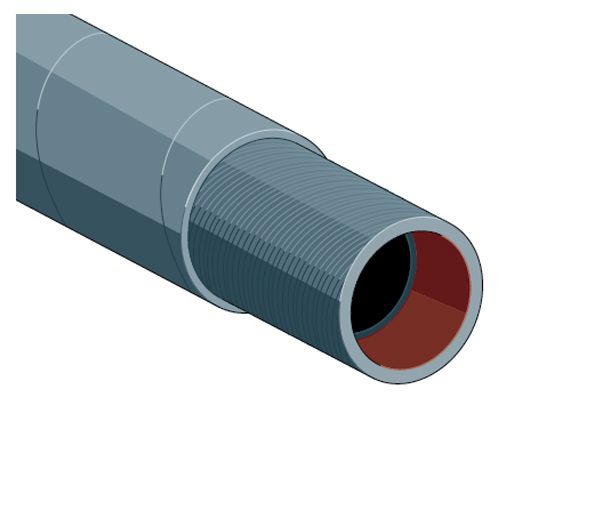

Sources of errors in the skiving

- Dull skiving tools

- Incorrect skiving dimension

Potential risk by incorrect skiving

- Installation of the fitting on the hose – complicated

- Risk of leakage in the hose connection

- Premature tearing of the hose fitting

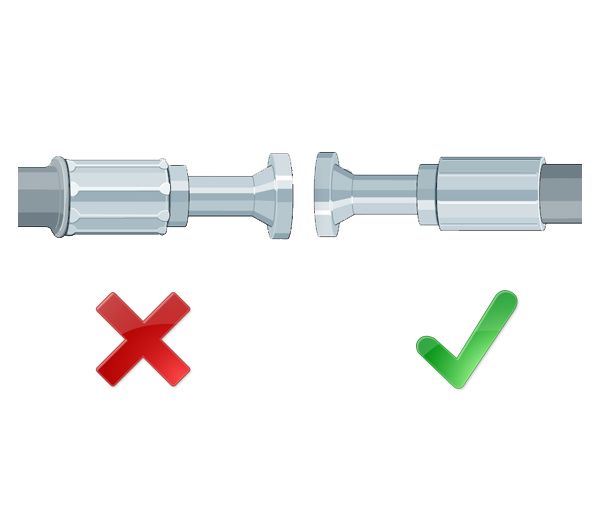

Crimping – the most important process of assembling

Sources of errors in the crimping

- Selected press die set incorrectly

- Compression level setting inaccurate

- Geometry of the pressing die set incorrectly

- Die set is worn out, deformed

- Multiple injection

- Throat depth not reached

Potential risk by incorrect crimping

- Installation of the fitting on the hose – complicated

- Risk of leakage in the hose connection

- Premature tearing of the hose fitting

- Cut injuries to sharp-edged pressing bars

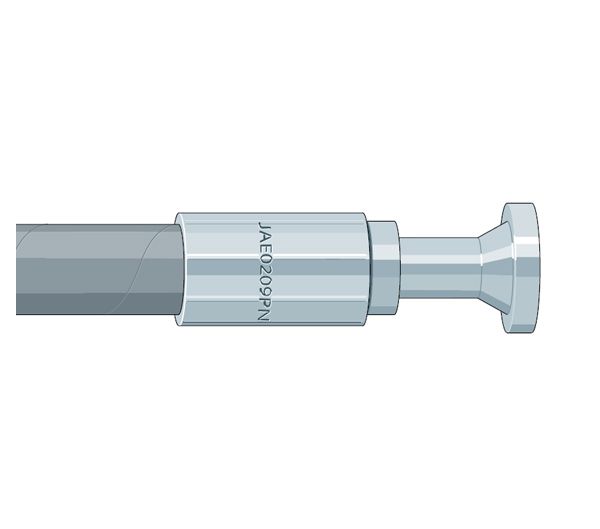

Marked hose assemblies

Cleaned hose assemblies

Securely pressed fitting

Due to DIN EN ISO, each hydraulic hose assembly has to be permanently marked with the name or logo of the manufacturer, manufacturing date and maximum working pressure of the hose assembly.

By marking the installed hose assembly, the service life can be better proofed. The clear identification is an essential part for the integrity of the hydraulic system, and most importantly the safety of people and equipment.

Advantages of the marking

- A clear identification of the hose line is possible

- Allows for quick and easy replacement

- Production date of the hose line is highly visible to everyone

- Safety in the installation with regard to compression

- Complies with all requirements of DIN EN ISO requirements

Potential risk by incorrect marking

- Incomplete information on technical

parameters - Marking can be permanently unreadable

- Marking is missing – generally not permitted

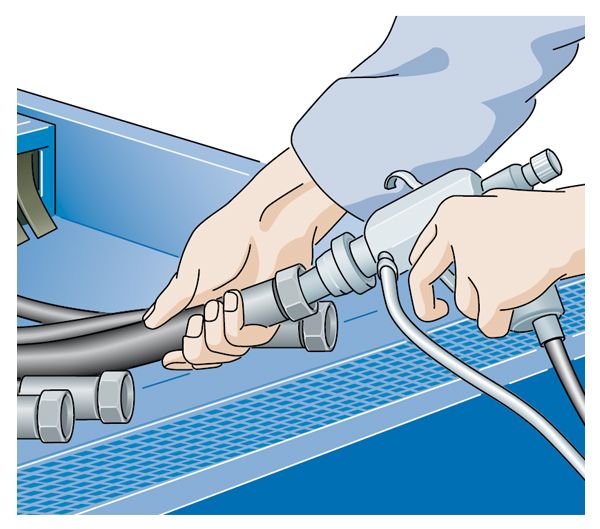

UNIFLEX cleaning machines remove contamination in the hose so the specified standards can be met.

All hose assemblies are then free from cutting debris, dirt, liquids and contamination.

Advantages of cleaning

- Clean, washed hoses

- Internal cleaning with fire retardant

- Achieving a clearly defined purity according to:

ISO 4406, ISO 4405 or NAS 1638 or special standards.

Uncleaned hoses can damage a machine, which can lead to the failure of the entire hydraulic system!

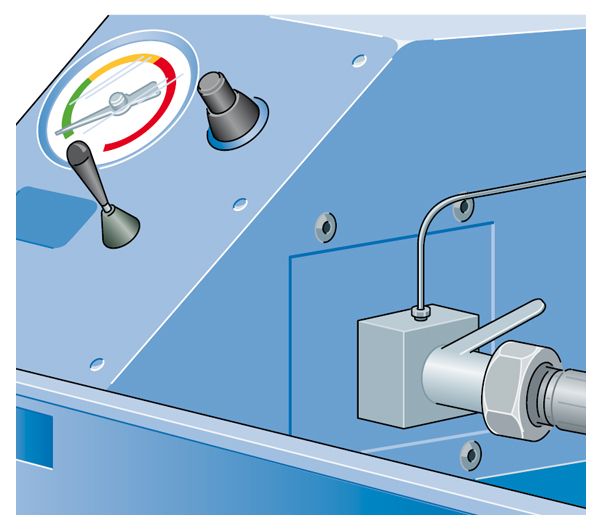

Modern UNIFLEX test benches offer various manifold options and allow flexible testing with adjustable proof pressures.

Tested, and if required, certified hose assemblies guarantee safety when in use.

Advantages of the test

- Test results are included in a report for customer documentation

- Preservation of pipe by use of neutral cleaners

- Tested products guarantee safety when using

Cleaned and tested hose assemblies and incorporated cap guarantee safe usage.